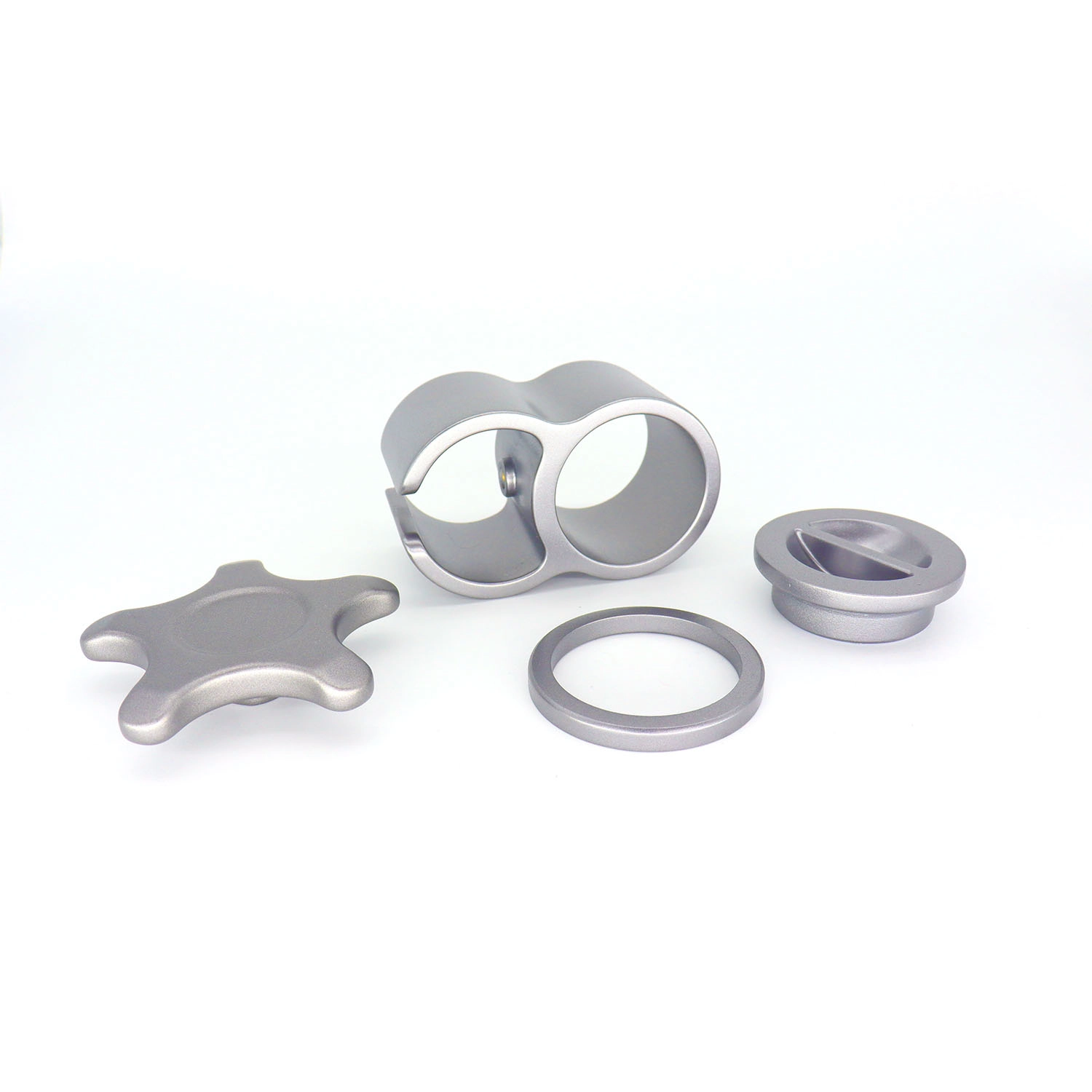

Prototype part

Prototype parts serve as a critical phase in product development, transforming three-dimensional design blueprints into tangible prototypes.

Introduction to Prototype Parts

Prototype parts serve as a critical phase in product development, transforming three-dimensional design blueprints into tangible prototypes. These prototypes validate design feasibility, structural integrity, and aesthetic appeal. Their primary role is to accelerate time-to-market while mitigating risks associated with mass production. Widely utilized across industries such as industrial design, mechanical engineering, consumer electronics, and more, prototype parts act as a vital bridge connecting conceptualization with production.

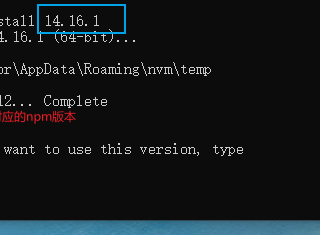

Operational Principles of Prototype Parts

The fabrication of prototype parts leverages cutting-edge manufacturing technologies, including 3D printing (SLA/SLS/FDM), CNC machining, and vacuum casting. These processes convert digital models into physical entities through layer-by-layer deposition or CNC programming. Key principles emphasize:

• Precision: Achieving accuracy within ±0.1mm to align with design specifications.

• Rapid Iteration: Shortening lead times (typically 3–7 days) to facilitate quick design refinements.

• Functional Testing: Enabling assembly, stress, and surface finish evaluations.

• Flexibility: Accommodating design modifications based on feedback.

Applications Across Industries

Prototype parts are integral to validating products across diverse sectors:

• Consumer Electronics: Testing casings for phones, headphones, and wearables.

• Automotive: Validating interior components and functional parts.

• Medical Devices: Assessing surgical tools and ergonomic designs.

• Toys & Cultural Products: Simulating complex geometries and articulation mechanisms.

Core Features & Functions

Prototype parts deliver:

1. Ultra-Precision: Tight tolerances for flawless fit and function.

2. Speed: Accelerated prototyping cycles for rapid innovation.

3. Simulation Capabilities: Realistic testing of mechanical performance and finishes.

4. Adaptability: Streamlined updates to address design flaws.

Design Considerations

Effective prototype design adheres to:

• Structural Integrity: Avoiding intricate undercuts or enclosed cavities.

• Material Optimization: Selecting plastics (ABS, PC, PA) or metals (aluminum, stainless steel) based on thermal, strength, or weight requirements.

• Tolerance Management: Ensuring seamless assembly through strategic clearances.

• Cost Efficiency: Balancing precision with budget-friendly processes.

Material Selection Guide

Materials are tailored to application demands:

• Engineering Plastics: ABS, PC, PA (heat resistance, durability).

• Resins: High-resolution SLA resins for intricate details.

• Metals: Lightweight aluminum or robust stainless steel alloys.

• Silicone Molds: Cost-effective for low-volume flexible parts.

Choosing a CDMO Partner

Selecting a Contract Development and Manufacturing Organization (CDMO) hinges on:

1. Technical Expertise: Mastery of SLA, CNC, and multi-axis machining.

2. State-of-the-Art Equipment: Advanced machinery for superior surface finishes.

3. Responsive Support: Proactive design optimization feedback.

4. Transparent Pricing: Clear cost structures without hidden fees.

5. Data Security: Non-disclosure agreements safeguarding intellectual property.

OEM vs. ODM Services

• OEM (Original Equipment Manufacturer): Produces parts strictly per client-provided specifications.

• ODM (Original Design Manufacturer): Offers end-to-end solutions, from concept refinement to scaled production.

Sector-Specific Solutions

Customized strategies include:

• Rapid Iteration Programs: 72-hour prototyping for consumer electronics launches.

• Complex Geometry Solutions: Topology optimization for challenging geometries.

• Low-Volume Production: Vacuum casting or resin infusion cutting costs by over 50% versus tooling.

By integrating these services, businesses bridge the gap from ideation to market-ready products, ensuring competitiveness and innovation.

Reviews

There are no reviews yet.