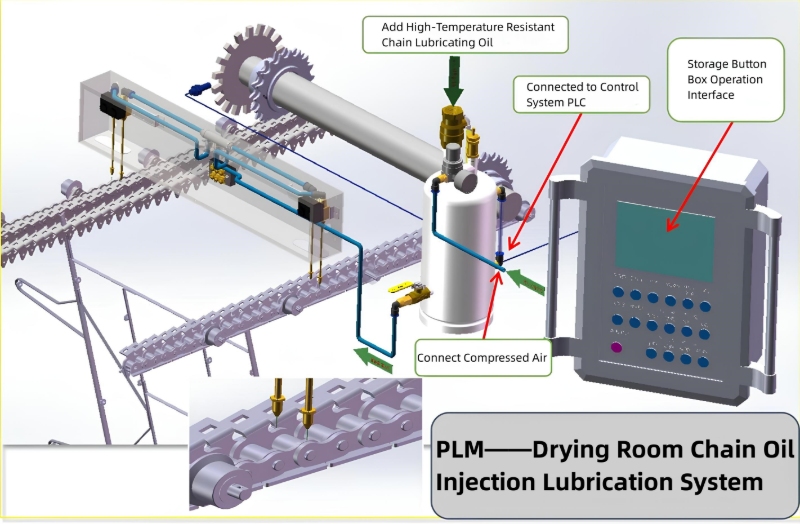

Oil Injector for Drying Room Chain Working Principle

The oil injection system adopts PLC automatic control. When the flower rack sprocket rotates one tooth, the sensor transmits a signal to the PLC, and the signal is fed back to the oil injector solenoid valve through the PLC. The action of the solenoid valve automatically drips oil to lubricate the flower rack chain.

Produce Description

1. Less maintenance work, reduced fuel consumption, reduced cleaning costs, and extended chain usage Life expectancy, making positive contributions to environmental protection; Optimal system control; Reduce the risk of accidents and improve workplace safety.

2. Extend the service interval; The oil discharge volume of each oil outlet can be adjusted to meet their respective needs (0-9999 ml/1000 h) to avoid thin oil pollution; The menu operation is simple, and precise oil injection can be controlled from 0 to 120 times/minute through PLC feedback,

3. It has an automatic timing oil injection function to ensure the permanent lubrication condition of the chain.

|

Characteristics of The Oil Injection System |

Customer Usage Advantages |

|

Using PLC Automatic Control to Complete Oil Injection Program |

Easy Operation |

|

The Sensor automatically detects the completion of oil filling and closing function |

Prevent excessive lubrication from contaminating products |

|

Accurate Oil Dripping and Proper Lubrication |

Extend the Service Life of The Chain |

|

Control the amount of oil dripping by adjusting the pressure of the oil injection tank |

Simple Adjustment Operation and Low Cost |

Reviews

There are no reviews yet.