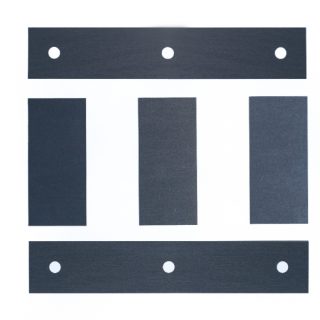

Slideway

High Precision and Accuracy: Precision slideway assembly ensures that machine components move with minimal deviation, providing exceptional accuracy and repeatability in linear motion.

Advantages of Precision Slideway Assembly Service

– High Precision and Accuracy: Precision slideway assembly ensures that machine components move with minimal deviation, providing exceptional accuracy and repeatability in linear motion.

– Superior Rigidity: The design of precision slideways offers excellent resistance to torsional and lateral forces, ensuring stability and minimizing vibration.

– Longevity and Durability: High-quality materials and precise manufacturing processes result in extended service life and reduced maintenance requirements.

– Customization: Precision slideways can be tailored to specific application requirements, offering flexibility in terms of sizes, configurations, and materials.

Features of Precision Slideway Assembly Service

– Material Selection: High-strength materials such as steel, aluminum, and various alloys are used to ensure durability and load-bearing capabilities.

– Surface Treatment: Surface treatments like hardening and corrosion resistance enhance the performance and longevity of the slideways.

– Lubrication Systems: Options for manual or automatic lubrication systems ensure smooth operation and reduced friction.

– Design Flexibility: Various types of slideways (e.g., dovetail, linear guide) are available to meet different application needs.

Manufacturing Process of Precision Slideway Assembly Service

1. Design and Engineering: Utilizing advanced software (e.g., AutoCAD, SolidWorks) to create detailed blueprints and ensure accuracy.

2. Material Preparation: Selecting high-quality raw materials based on mechanical properties and cleaning them to remove impurities.

3. Machining and Fabrication: Precision machining using CNC machines to achieve tight tolerances and high surface finish.

4. Quality Control: Rigorous inspection at every stage using advanced tools to ensure accuracy and quality.

5. Assembly and Testing: Careful assembly of components followed by testing to simulate real-world conditions.

Applications of Precision Slideway Assembly Service

– Machine Tools: Used in lathes, milling machines, and grinders to facilitate precise movement of cutting tools and workpieces.

– Metrology and Inspection Equipment: Integral to coordinate measuring machines (CMMs) and optical comparators for accurate positioning during quality control.

– Aerospace and Defense: Employed in aircraft assembly, missile guidance systems, and weapon mounts where reliability and precision are critical.

– Automotive and Industrial Machinery: Used in various industrial applications where high precision and durability are required.

Wuxi Okin Hydraulic Machinery Co., Ltd. is located in Cangxia Industrial

Park, Dongting Town, Xishan District, Wuxi City, covering an area of 6,000

square meters, adjacent to Wuxi East Railway Station and Shuofang Airport, close

to the Beijing-Shanghai Expressway, with convenient transportation and beautiful

environment.

The company was founded in 2010, since its inception has been in the

automotive industry development, with many years of experience in cooperation

with domestic and foreign OEMs. The company has 100 employees, including 26

professional and technical personnel, equipped with Auto CAD, UG, Solid Works,

Pro-E and other software to assist in the design, but also equipped with three

coordinates, profilers, imaging instruments to monitor product quality. 2018 we

have obtained the IATF16949 quality system certificate, but also obtained 15

utility patents and 1 invention patent certificate. We have also obtained 15

utility patents and 1 invention patent certificate.

Subsequently, we will further improve the automation and intelligence of the

workshop and provide automation services for our customers to achieve win-win

cooperation In many years of cooperation with the automotive industry, we have

been committed to improving the technology forward-looking and quality

management level. The company now not only has a large-scale machining capacity,

but also has automation equipment and intelligent equipment design and

manufacturing capacity. We can provide extended services such as automation

inspection and assembly while providing machining services. Thanks to our rich

machining experience and development capability, our business has been expanded

to many industries such as automotive, military, home appliances and toys.

Reviews

There are no reviews yet.